CNC Machining Vietnam

Precision and affordability are important for manufacturers in their quest to scale while ensuring quality without breaking the bank in the process. CNC machining Vietnam is quickly becoming a world leader in sourcing professional, precision, and affordable CNC machining solutions. Vietnamese manufacturers specialize in Swiss Precision Machining CNC to offer unmatched precision, efficiency, and cost-effectiveness.

What is Swiss Precision Machining?

CNC Swiss precision machining is an advanced method that allows for the production of complex parts with extreme precision. The method was first used in Switzerland for the watch business and has since branched out to medical, aerospace, automobile, and electronic industries.

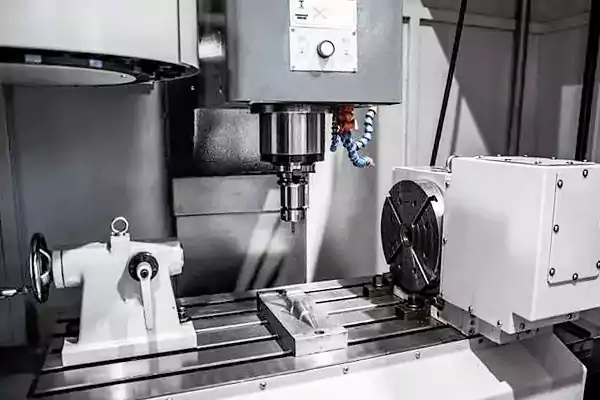

Unlike traditional CNC lathes, which rotate the workpiece against a tool while it is locked in place, Swiss-style CNC machines hold the workpiece in place, enabling them to machine on multiple axes simultaneously. This unique process helps readers reduce errors and increase productive output.

List of reasons to select CNC machining

Vietnam has quickly evolved into a premier location for precision CNC machining for a few reasons:

Cost-Effective Manufacturing

So, the experts say whoever wants to outsource CNC machining should take CNC machining services in Vietnam. It will allow you to save money without any sacrifice in quality since skilled labor is available at a fraction of what you would pay in Western countries.

High-Quality Standards

Manufacturers in Vietnam implement rigorous quality control processes to ensure that every component adheres to global quality standards. High accuracy and durability are also common features of Advanced CNC Swiss Precision Machining techniques due to allowing for tight tolerances and impeccable finishes, which can bring ease of mind to a wide variety of industries.

Advanced Technology & Equipment

Many manufacturers in Vietnam invest in advanced CNC machinery, such as Swiss-style lathes, and multi-axis milling centers used with state-of-the-art automation production lines. This enables fast-paced historical production with exacting precision.

Other capabilities and industry expertise

In Vietnam, CNC machining companies serve a variety of industries, such as:

- Aerospace: Components with very tight tolerances for airplanes.

- Medical: Surgical tools and devices.

- Automotive: Motor parts and mechanical components

- Electronics: Little things for circuit boards.

Fast Turnaround Times

Vietnamese CNC Machining Manufacturers can expeditiously deliver projects and bring proven production processes and skillful labor for their work. As a result, businesses can reduce lead times and satisfy market demands efficiently.

Vietnam Precision Machining CNC Swiss Capabilities

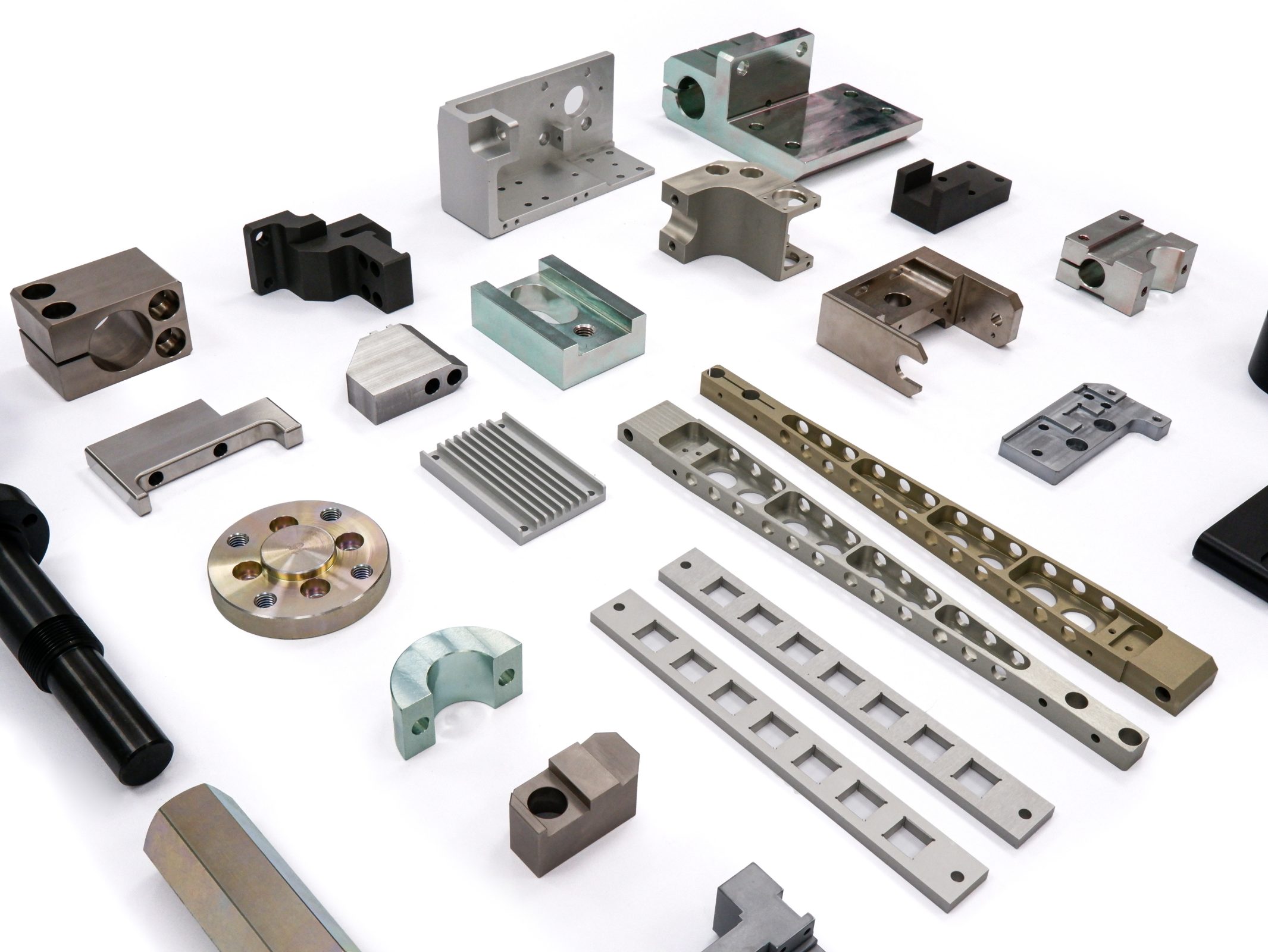

These are some of the precision machining services provided by Vietnamese CNC machine shops:

- Swiss CNC Turning: Best for small, complex components with tight tolerances.

- Multi-Axial CNC milling: Allows manufacturing of complex geometries and shapes.

- Precision Drilling & Tapping: Guarantees precision for component assembly.

- Surface Finishing & Coating: Anodizing, plating, and polishing to provide improved durability.

- Prototyping & Mass Production: Enables both low-volume and high-volume production runs.

Advantages of CNC Machining Vietnam

Scalability & Customization

Whether working on a single prototype or moving into mass production, an experienced manufacturer in Vietnam specializes in offering flexible solutions that are tailored to the requirements of your project.

Stringent Quality Control

They are a top-tier CNC Machining Vietnam facility following ISO-certified processes for their services. It is guaranteed that each part meets customer requirements through regular inspections and testing.

Eco-Friendly Manufacturing

CNC machining companies in Vietnam are developing sustainable practices in their production by adopting eco-friendly methods for minimizing their waste production and making efficient use of the material they use.

Seamless Global Shipping

CNC machining companies in Vietnam can ship the parts globally quickly and economically with established logistics networks.

How to Select a CNC Machining Partner

Factors to Choose a CNC Machining Partner in Vietnam

- Practical Experience: Seek a company that has a proven history in CNC Swiss Precision Machining.

- Certifications & Standards: Check that the manufacturer adheres to international quality standards.

- Customer Reviews & Testimonials: Read through feedback from previous clients to get an idea of their reliability and service quality

- Machinery & Capabilities: Look for a provider whose CNC machining equipment is advanced enough to meet your needs.

Conclusion

With its high-quality, competitive pricing, and scalability, Vietnam’s CNC machining industry is taking precision manufacturing to the next level. So whether you need CNC Swiss Precision Machining for aerospace, medical, automotive, or electronics applications, the manufacturers in Vietnam, such as TDB Machining Tec, can deliver quality, cost-effective services that meet your needs.

Working aligned with a reliable CNC machine shop in Vietnam offers seamless best precision in an Exotic, cost-effective, and efficient manner assuring competitive advantage in the current international scenario.

For more updates and information visit our Facebook page.